The Development of the Sash Window

|

Fig.1: Left : A late 17th century ‘cross’ window with leaded lights. The window is divided into four ‘lights’ by a central post or ‘mullion’ and a horizontal cross bar or ‘transom’. Each light contains a wrought iron frame or ‘casement’ with small pieces of glass held together by H-section strips of lead known as ‘cames’.

Right : A late 17th century ‘eight-over-eight’ paned sash window. When sash windows emerged at the end of the 17th Century many cross windows were taken out and replaced by sash windows such as this one. The removal of the mullion and transom created a single light which was glazed with two timber frames or ‘sashes’. The glazing bars were very thick and numerous, and the panes were small. Initially only the lower sash was hung on cords and counterbalanced by hidden weights to allow it to be raised and lowered with ease.

|

|

|

|

Fig.2 Early 18th century sash windows. As the price of larger sheets of glass fell, the ‘six-over-six’ window became common, and the ‘four-over-four’ (right) was not unknown. After 1709 the windows of buildings in London were required to be set back four inches from the face of the wall, but the box remained exposed. Double hung sashes (with both sashes hung on cords) predominated. From about 1710 to 1730 the segmental headed arch (right) was popular, with both four- and six-paned sashes. |

|

|

|

Fig.3 Left: A late 18th century six-over-six sash window with hidden sash boxes (their position indicated by dotted lines). The flat arch was reintroduced with the accession of George 11 (1730), and after 1774 windows were required to be recessed behind an outer nib of masonry to prevent the spread of fire from one to another. These developments, together with the introduction of finer glazing bars, led to the emergence of this style of window which is so characteristic of the mid-Georgian period.

Right: A Regency window with

‘margin lights’. Excise duty on glass generally favoured the use of small

light panes of crown glass, so the introduction of small margin lights around

a large central pane, which was fashionable in the 1820s, was an elegant but

significantly more expensive departure from the usual six-over-six sash

window. |

|

|

Introduction

Our historic towns and villages are being resolutely desecrated by an army of window salesmen, window manufacturers and misguided builders, as well as by the owners of historic buildings themselves.

Windows are an important part of a building’s history and can be read like a book; they tell us not only of the changing architectural taste and style but also of social hierarchy, building economics, craft ingenuity and technical advances, and of the ways in which houses and certain building materials were taxed. They are the single element which most serves to establish the character of a building, and so, often, of a whole district.

Now, crude and unsympathetic mass-produced windows in wood, metal and plastic, are everywhere being substituted for original windows, with disastrous results. Paradoxically in many parts of the country those so called ‘home improvements’ actually reduce the value of old and historic houses, and this trend is spreading rapidly as fewer people want to buy houses which have been badly altered. Even estate agents have come to realise the financial value of retaining original features.

Where buildings are listed the penalties for removing windows can also include criminal prosecution.

Historical Development

The earliest windows were essentially very small apertures in a wall (a ‘wind-eye’ or ‘wind-hole’), sometimes protected by bars, shutters, curtains, oiled paper or cloth, and provided a modest amount of light and a restricted view. Although glass has been manufactured in Britain since the 13th Century, glazed windows remained a rarity until the 16th Century, when leaded lights set in metal ‘casements’ or frames began to be less exclusively the preserve of the very wealthy. From these humble origins the domestic window grew into an architectural element which could be instrumental in proclaiming the status of its owner. The generally horizontal format of Elizabethan times gave way to the more elegant vertical proportions, which came to predominate during the Georgian period. The relationship of window area to wall area also varied enormously, according to need, fashion, and status (the pre-eminent example of which is the Elizabethan ‘more glass than wall’ Hardwicke Hall).

The vertical proportions of the typical early 17th century window with its timber frame, mullion and transom, and timber or wrought iron casements, made it admirably adaptable to the newly fashionable sliding sash window, and many were replaced in the late 17th Century. The fashion took such a hold that early timber framed buildings which were not so readily adapted often had sash windows quite inappropriately inserted, involving the mutilation of the structural frame. At the same time the opportunity was sometimes taken to cover the front of a timber frame building with an elegantly proportioned skin of brickwork or stone. This usually bore little relation to the building behind, so that in many towns there are to this day rambling Elizabethan houses masquerading behind refined Georgian facades.

Sash Windows

In the earliest type of sash window the top sash was fixed and the bottom sash slid upwards in a groove, held open in position by means of pegs or metal catches. These existed well before the introduction in the latter half of the 17th Century of the ‘double hung’ sliding sash window as we know it today, with both upper and lower sashes hung on cords and counter-balanced by hidden weights. An intermediate ‘single-hung’ type provided the same counterweight mechanism but for the lower sash only, and the upper sash was allowed to drop down a few inches without assistance.

Although the double-hung sash window system which evolved has remained essentially unchanged for over 250 years, its position in the wall changed significantly. At first the window was placed on the outer face of a brick wall, so the whole of the sash box was visible externally, giving the window a broad timber surround (compare the top right window opposite with those below). However, after The Great Fire of London the exposed box was seen as a fire risk, helping to spread fire from one window opening to another, and in 1709 the London Building Act decreed that box sashes should be set back four inches from the face. This applied originally in the Cities of London and Westminster only, but eventually spread outwards as similar legislation was adopted by urban centres further afield.

|

|

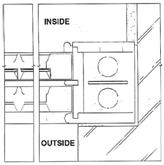

Fig4 Horizontal section through a late 19th century sash box and part of the lower sash. The detail shows how little of the sash box can be seen externally |

The London Building Act of 1774 required sash boxes (the boxed frames which housed the weights) to be placed behind the masonry. In effect, the legislation meant that the glazed area of the window could be made wider, with almost the whole of the sash box tucked out of sight behind the outer leaf of masonry with very little timber showing (figs. 3 & 4). Like the Act of 1709 the requirement was gradually adopted more widely. However, as legislation is frequently ignored, especially in outlying parts of the country, the positioning of the box cannot always be relied on as a means of dating buildings.

Glass

The size of window pane (and therefore the overall appearance of the window) was not so much influenced by fashion as by the limitations of glass production and by its price. By 1701 'plate glass' was being sold in London for mirrors in plates of up to 6ft long, and at Hampton Court Palace (1689-94) it was possible for Wren to choose plate glass for the windows of the Queen's Drawing Room. However this type of glass was expensive to produce, involving casting molten glass over a bed of sand, and then grinding it down and polishing it laboriously to produce a perfect finish. At Hampton Court smaller panes of 'crown glass' were used in rooms of lesser importance. This glass was much less expensive as it did not require polishing, but it could only be produced in small sheets due to the size of the 'crown', the circular disk of glass from which the panes were cut.

|

|

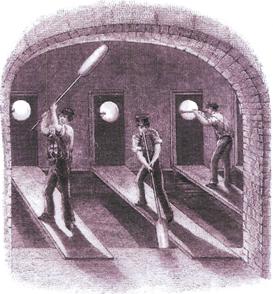

Fig.5 Crown glass-making C.1860. Crown glass was made by blowing a bubble of glass, opening one end, and gradually widening it out until a large flat disc known as the 'crown' was formed. Small panes could then be cut from the crown.

|

It was possible in 1703, to choose from twelve different types of window glass regularly available on the open market. However, the introduction of excise duty on glass by weight at the middle of the 18th Century favoured the crown process, which allowed the thinnest panes of glass to be produced, albeit of a very limited maximum size. Being the cheapest, it should not surprise us to find that crown glass was quickly adopted by the builders of that time, thus influencing the appearance of buildings of the period.

The typical Georgian window in everyday domestic work came to be the double hung sash with six panes in the upper and lower sash frame (fig.3). In his Complete Body of Architecture (1750), Isaac Ware had written that "as much glass should be seen, and as nearly a continued body as possible".

|

|

Fig.6 Cylinder glass making C.1860. Cylinder glass was made by swinging a freshly blown glass bubble so that it elongated by centrifugal force. Both ends of the cylinder were then cut off to form a tube which was then split down one side from end to end and opened out to form a flat, square sheet.

|

With improvements in its production, the cost of cylinder glass began to fall and after the removal of excise duties in 1845, there was less incentive to use the small thin panes of crown glass. A decade later a correspondent to The Builder wrote: "Formerly, when sashes were made in twelve lights, we could get crown glass put in, but when the duty came off glass and cheapened it, the public taste ran for larger sized squares to look through, and consequently crown-glass had to give way to sheet. It is true we now have large squares, but a very bad appearance." (The Builder, 14th April 1860.)

Glazing Bars

The earliest glazing bars of both sash and casement windows were numerous and thick. On the inside they were moulded to deflect light and reduce glare. On the outside they were rebated to take the glass pane, held in place by putty as it is to this day.

Over the years the cross-sectional area of glazing bars gradually reduced, eventually reaching a point in the late 18th and early 19th Century when the width was as little as 13mm (half an inch). As a result these narrow bars were often made of hardwood or even metal. At the same time the size of the glass panes increased considerably.

|

Fig7. Historic glazing bar profiles (By courtesy of The Brooking Collection) |

|||||

|

|

Source |

Type |

Date |

Width |

Depth |

|

|

Hampton Court |

|

1689-94 |

40mm |

42mm |

|

|

Cupola of Eagle, Mitcham |

|

1705 |

30mm |

33mm |

|

|

Berners London |

|

c1750 |

22mm |

44mm |

|

|

The Barons Reigate |

|

1721 |

19mm |

32mm |

|

|

Bedford Square London

|

|

1775-86 |

15mm |

40mm |

|

Fig8. Modern glazing bar profiles (to the same scale) |

||||||||||

|

|

Source |

Type |

Date |

Width |

Depth |

|||||

|

|

|

Typical Victorian ‘Iamb’s tongue’ |

|

15mm |

35mm |

|

||||

|

|

|

Typical modern double-glazing (reproduction) |

|

45mm |

64mm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Glazing Fashions

With the introduction of cheaper glass in larger sheets in the early 19th Century it became the custom to remove or reduce the number of glazing bars in the lower sash, to make an early form of ‘picture window’ (fig. 1 0). When, during the 1820s and 30s the top sashes were treated in the same way, it became necessary to modify their construction to cope with the greater stresses imposed on their joints by the weight of the heavier glass. So the side rails were continued down, projecting below the junction with the bottom rail, allowing the joint to be supported from below as well as from above. These projections were called ‘horns’ and took on a progressively more elaborate form.

|

|

|

|

Fig.9 Late 19th century sash windows with large panes of sheet glass. Notice the short projection of the sides or ‘stiles’ of the sash below the meeting rail of the upper sash. Known as ‘horns’, these elegantly shaped projections strengthened the joint where the rail was morticed into the stiles |

|

The return to small panes at the end of the 19th Century was to some degree a reaction to the vast sheets of plate glass being used in shop fronts. The architecture of the Queen Anne Revival, which was heavily influenced by the Arts & Crafts Movement led to the reintroduction of thick glazing bars in some buildings, and sash windows were once again placed on the face of the building, with boxes showing. These were often mixed with casement windows on the same red brick facade. Perversely the 'picture window' form of glazing was often used for the lower sash, with six panes in the upper sash.

|

|

Fig. 10 Left: A Georgian window with its lower sash reglazed. Georgian windows were often reglazed with larger sheets of cylinder or plate glass after 1845. Right: A late 19th century design typical of the 'Queen Anne Revival'. Glazing bar thickness and glazing pattern varied widely. The choice was entirely stylistic and was unrelated to cost or legislation.

|

Casement Windows

|

|

Fig. 11 Casement Windows: The left half illustrates typical Victorian details; the right half illustrates the much larger profiles of a typical modem 'storm-proof window.

|

Despite the popularity of sash windows, leaded lights and metal casement continued to be used throughout the 17th and 18th Centuries, predominantly for church windows. In domestic architecture their use remained rare (or at least discreet) until a series of romantic revivals made them fashionable once again, commencing with Georgian Gothic in the late 18th Century and the Gothic Revival a little later. Metal casements and leaded lights predominated in the Tudor and Jacobean revivals popularised in suburban housing in the late 19th and early 20th Century. Small-paned timber casement windows and sash windows predominated in the Queen Anne Revival from the 1860s, with timber casements growing increasingly popular from the last quarter of the 19th Century into the present age.

The development of the timber casement window echoes that of sash windows, with small panes being replaced by progressively larger ones with smaller glazing bars. Otherwise the design of timber casements remained essentially unchanged throughout the 18th and 19th Centuries. Opening lights were usually hinged at the side, separated from other lights in the same window by timber mullions. Fixed lights were rarely direct-glazed; each had its own casement even if it did not open. Unlike modern 'stormproof' windows, original timber casements never overlap the frame, and usually finish flush (fig.11). As a result the timber sections of old casement windows appear less bulky than modern ones.

Listed Buildings

Few people (including professional consultants) realise that if a building is listed, special consent is required for all works of demolition, alteration, or extension, including the removal and alteration of its windows. It is a criminal offence to undertake works to a listed building without consent. The Magistrates Court can impose a fine of up to £20,000 and imprisonment for up to 6 months, and the Crown Court can impose even more severe penalties. Both the owner and the contractor can be prosecuted, and unlike ordinary planning permission there is no 'four year rule' after which period action cannot be taken against alterations.

The consent, which is called 'listed building consent', is not required for works of routine maintenance or repair such as re-puttying a window, repainting it in the same colour, or replacing individual panes of broken glass. However, repairs which involve an element of alteration will require consent, and building owners would be well advised to inform the local authority if they propose to carry out extensive repairs and any alterations, especially if windows are to be replaced for whatever reasons.

Maintenance and Repairs

Complete replacement of timber windows is seldom necessary, as decay almost invariably starts at the bottom and works upwards, and the lower components will need replacement and repair long before the upper parts. Indeed, complete replacement may actually be counterproductive, as some replacement windows inserted in the last thirty years have now decayed, whereas many windows from the 18th Century and earlier still survive.

Decay

A detailed inspection of windows should be carried out regularly, probing vulnerable areas with a sharp instrument for signs of decay. This will usually take the form of wet rot, which affects both softwoods and hardwoods, and occurs where:

- water is allowed to stand on horizontal planes, such as sills

- paintwork has cracked, and at joints

- moisture is attracted by capillary action and becomes trapped, for instance between a timber sill and the masonry below

- adjoining masonry is damp for long periods

- condensation persistently forms on the inside face of the glass especially in bathrooms and unheated rooms.

Wet rot is recognisable by slight ripples and discoloration of the paintwork, and the underlying timber becomes soft, breaking up when probed. However, paint deterioration has many causes, and does not necessarily indicate rotten wood.

Other forms of decay include the wood-boring larvae of certain types of beetle, and dry rot, a specific type of fungus.

Dry rot rarely affects windows, but is sometimes found behind sealed shutters and in the boxes of sash windows when there has been an outbreak of fungus elsewhere in the building. Treatment is more complex than for wet rot and is best dealt with by a historic building specialist.

Wood-boring insects pose less of a problem than fungal attack: the one most likely to affect windows is furniture beetle larvae or

‘woodworm’, although those of death-watch beetle may also attack oak and other species of hardwood. Both are encouraged by damp conditions and are often found in association with wet rot.

Movement

Movement in masonry or timber-framed walls may lead to the distortion of the window, causing it to jam, and in some cases actually making the glass break. However, old buildings can tolerate a surprising amount of movement without any trouble, and remedial works such as underpinning can do more harm than good, particularly to old buildings. Movement may also be old and no longer active, and the windows may have adjusted to suit their realignment. If they continue to work effectively, all that is require is to check their joints for gaps to be filled, and that their paint covering is sound. Only a structural engineer who is experienced in dealing sensitively with old buildings will be able to give reliable advice as to whether further work will be required.

Maintenance

Timber windows require regular maintenance to keep them in working order. Sticking sashes in unused buildings will often contract slightly and work loose once heat and ventilation are reintroduced. The breakdown of paint or putty should be dealt with promptly as this may lead to decay of the timber underneath.

Timber Repairs

Treatment for timber decay should follow the guidelines set out by the Building Research Establishment. In particular:

- Locate and eliminate sources of moisture

- Promote rapid drying of the affected area

- Where timber has decayed, cut back to sound timber, removing no more than is necessary

- Use preservative-treated timber in repairs and treat remaining timber which may be at risk with a fungicidal or insecticidal preservative.

Decay Treatment

Small areas of decay can be scraped out and the remaining sound timber treated with a suitable preservative; when this has dried out the decayed area can be primed and built up with a filler. Larger voids which are not too near a joint can be partially filled with a timber patch, followed by filler at the edges. Traditional fillers were made of white lead paste and linseed oil putty, sometimes with chalk or sawdust to provide bulk. Of the modern fillers the two-pack systems (epoxy resin or polyurethane) are more durable than ready-to-use types.

SPAB ADVICE ON REPAIRS

From Technical Pamphlet 13, The Repair of Wood Windows

- Where decayed timber is to be removed to form a splice repair, the minimum amount of existing timber should be removed to allow an effective repair to be formed

- Always work new material to the line of the existing and avoid unnecessary trimming of the original timber: repairs should follow any existing deformations in the line of the window

- The timber used in a repair should match the original as closely as possible as the joint between the two is likely to fail if the two species have different rates of expansion and contraction: they should be of the same species; the line and density of the grain (the number of growth rings) should match; and the new timber should be well seasoned

- As with all joinery work, timber with shakes, fissures, warping, heartwood, sapwood or numerous large knots should be avoided

- When carrying out a repair, try to ensure that the structural integrity of the window is maintained and that the window continues to work as it was designed to

- Where possible, spliced repairs should be designed to ensure that moisture is directed towards the outer face of the timber and that moisture does not lie on the repair joint

- The length of the splice is governed by the section of timber and the nature of the component being repaired: it should be designed to ensure an effective bond between new and existing sections of timber

- Wherever possible, spliced repairs should be formed which include mechanical fixings (such as timber pegs/dowels or non-ferrous screws/pins) as well as glue: screw or pin fixings should ideally be made from the inner face of the window

- Avoid previous design faults when carrying out repairs: consider modifying a method of construction (or a previous repair) where it is liable to lead to further decay

- If possible, repairs to window frames should be formed in situ especially where the frame is built in and cannot be removed without damaging either the window or surrounding wall: in general, casements and sashes can be removed quite easily without damage to be repaired on site or in a joiner's workshop

- Where windows are to be dismantled as part of the repair process, always mark and record the constituent parts before dismantling, especially where a significant number of windows are to be repaired: similarly, always number glass panes/quarries before removal.

Repainting

When repainting it is seldom necessary to strip a window completely; only loose and defective areas of paint, putty, or filler need be removed. If it is decided to strip the paint, bear in mind that old layers of paint also provide a record of colour schemes used in the past and may be analysed. Some part should always be kept for posterity.

Old paint can be stripped using solvent strippers but the timber should be cleaned down thoroughly afterwards, otherwise the residue may tend to loosen any subsequent coat of paint. Blow lamps should always be avoided in historic building work due to their fire-risk; even hot air strippers can cause ignition of dust in concealed cavities (such as a sash window box); they are also liable to crack crown glass due to its extreme delicacy. On no account should windows be stripped by immersion in a bath of caustic soda (or of any other chemical paint stripper) as this method damages the timber and dissolves the glue from their joints, weakening them.

Where the existing paint is likely to contain high levels of lead (most pre-war paints did), burning it off will cause toxic fumes, and rubbing down with abrasive paper will generate toxic dust; the only safe method is to use wet abrasive paper.

Lead-based paints and primers, which provide the best protection, cannot be legally used today, except in special circumstances on some listed buildings. The modern alkyd paint systems offer an initially good level of durability, but degrade relatively quickly with age, and require a shorter repainting cycle than lead-based paints. Alkyd primers are unsuitable for use on hardwoods, so an aluminium-type primer should be used first, always making sure that the paint coats which follow are compatible with the primer.

Glazing

The inherent qualities of hand-made glass contribute much to the liveliness and character of historic buildings. As crown glass is so thin and delicate, extreme care should be taken to avoid damage during building operations. Ideally, cracked panes should be left in situ, unless too badly damaged to save, or where the panes have to be removed in order to repair the glazing bars. If old putty cannot be removed by hand, a solvent paint stripper or soldering iron may be used to soften it. Several applications may be required.

Original glass provides the best replacement for broken panes, and where a window has decayed beyond repair, its old glass should always be set aside for re-use. Second to this is new glass which, with care, may be found to closely match the original material, but avoid material which is too reamy or over-distorted. New cylinder glass can still be obtained, but commercial production of crown glass ceased recently and this type may be unobtainable.

Regular commercially available new glass is unlikely to provide a suitable match. Greenhouse glass and some Eastern European glass can be suitable although supplies of the latter are variable in supply and quality, and a few specialist suppliers offer modern substitutes for old glass, mostly in imitation of cylinder glass (since the character of the hand-blown and spun crown glass is impossible to duplicate by any other process).

|

|

Fig. 12 Replacement windows (right) contrast sharply with the originals (left) not only in the number of panes but also in their detail. The ‘glazing bars’ in the double-glazed windows (right) are made of strips of plastic inserted between two sheets of glass and bear no relation to real glazing bars, and the window seems flat and lifeless. It is as if the manufacturers never learned to use their eyes. |

Other Repairs

Sash cords should be given attention at the same time as any extensive repairs and replaced if necessary. If a considerable amount of glass has been replaced it will be necessary to adjust the weights. Traditionally, the combined downward pull of the weights serving the top sash should be slightly more than the sash itself, including glass, so that it has a tendency to close easily. The weights serving the lower sash should be slightly lighter than the sash itself for the same reason.

DO’S AND DON’TS

- Repair wherever possible, rather than replace

- Don’t alter door and window openings in proportion or detail as they help to establish character

- Retain and reuse all historic details, including old glass, window fittings and ironwork (such as balconies and balustrades), mullions and other features from the window and its surround

- Replace damaged or missing pieces with accurate modern reproductions or reclaimed originals that match those that have survived

- Paint windows, rather than stain them, as stains were not used historically.

- Do not double glaze windows: contrary to popular belief, double glazing is not an economical investment, and it is not required by current building regulations when making ordinary alterations to historic buildings

- Do consider, as an alternative to double glazing, the installation of modern weather-stripping seals by a reputable specialist firm, who will if required also repair and overhaul your sash windows, including replacement of sash cords and adjustment of weights, at the same time

- Do consider, also as an alternative to double glazing, the installation of a lightweight secondary glazing system where the configuration of the window assembly permits.

Replacements

- Retain the original depth of ‘reveal’ (see fig. 12); this is essential if the character of the building is not to be destroyed

- If replacing whole windows use the original material, wood or metal, and avoid the use of inappropriate copies

- Ensure that glazing bars are of the appropriate thickness and profile (fig.8), which will usually be that of the glazing bars being replaced, but not in all cases

- If modern mass-produced sash windows are to be used, choose from the ranges of the very few manufacturers such as the Mill House Window Workshop who have managed to combine modern manufacturing techniques and standards with near authentic detailing

- Additional windows should be sympathetic in scale, design, and detail to the originals.

Thermal Improvements

Effective home insulation is a major priority for most home owners, both for comfort and economy, and to limit the waste of natural resources. The energy used to construct and heat buildings accounts for half of the total energy consumed in the UK; the by-products are carbon dioxide and sulphur dioxide emission from power stations, contributing to global warming and acid rain. The Government is committed to stabilising carbon dioxide emissions by the year 2000. In line with this commitment, Part L (Part J in Scotland) of the Building Regulations 'The Conservation of Fuel and Power' was revised to require improved energy saving measures which include, effectively, double glazing in all new homes. The Regulations are intended to apply also to existing buildings which are being converted from non-residential to residential, but they state that double glazing "could be inappropriate in conservation work and other situations where the window design needs to be retained".

Compensating Provisions

Existing buildings, historic or otherwise, where building work is not contemplated, remain unaffected. Where historic buildings are being converted to new uses, building control bodies have the discretion to look at each case on its own merits, and to require reasonable provision for limiting heat loss to be made. These include improved roof insulation, wall insulation (where appropriate), installation of more efficient gas or oil-fired boilers, more sophisticated central heating and domestic hot water controls, lagging of hot water pipe work and storage cylinders, draught-stripping windows and doors, and secondary glazing. Each of these improvements compensates for loss of heat through single glazing.

Older Properties

It has been estimated that 20% of home heating is lost through windows, much of it through the gaps around window frames; all the rest is lost through ventilated and suspended timber floors and through open chimneys. It can be seen that under these circumstances double glazing alone cannot address the question of heat loss, and that measures to prevent air infiltration will be more effective. Even heavy curtains can be a better investment.

Double Glazing

Double glazing has the advantage over single glazing in reducing down-draughts which are noticeable if sitting near a window in cold weather, and thermal insulation is improved. However, double glazing is really only effective if the gap between the two sheets of glass is 20mm - in most sealed units the gap is only 6mm. Sound insulation can be improved but in this case the gap needs to be 100-150mm. If the glass is too thin, the vacuum between the two sheets of glass causes deformation, which is clearly seen in reflections from each sheet; there can be a convex image superimposed on a concave image. Also, double glazing will always result in a double reflection.

Sealed units are expected to last 10 years. When breakdown occurs at the edge seal, moist air leaks into the cavity, and condensation occurs, causing misting of the glass and obscuring the view. Inexpert installation can cause the best quality sealed units to degrade more quickly. There are only two methods of installation approved by the Glass and Glazing Federation and which are in accordance with British Standards; neither of these involves the use of putty. From this it follows that, on this simple technical point alone, double glazing and existing sash windows do not go together.

A further technical problem lies in the fact that light also causes the edge seal of a sealed unit to degrade. It is recommended that the timber beads holding the glass in place should be at least 18mm wide; this leads to an overall glazing bar width of about 44mm (see fig. 8) whereas most glazing bars since the 18th Century fall into the 16-22mm range. Clearly this width might suit very early buildings, but is completely unsuitable otherwise.

Where it is absolutely essential, for whatever reasons, to employ double glazing (as opposed to secondary glazing) in an historic window with glazing bars, the least obtrusive solution is to use one of the proprietary window systems in which the sashes are fitted with false glazing bars on each side of the sealed glazing unit. The false glazing bars should follow the profile of the originals. To avoid the concave/convex double reflection mentioned earlier it is possible to introduce spacers within the sealed unit which align with the bars. However, some installers have found that windows exposed to strong sunlight can shatter where spacers have been fitted as differential expansion causes tension within the glass.

Draught stripping

|

|

Fig. 13 Section through a casement window fitted with simple draught-proofing seals.

|

Professionally fitted draught-stripping is one of the most effective methods of reducing air infiltration and therefore heat loss. Most companies replace the existing staff bead and parting bead with a section of their own, identical in size and shape but incorporating rubber, polypropylene or nylon brush seals, and capable of being painted. Sashes are taken out, grooves cut in the hidden edges and similar seals inserted, so that when they are replaced there is a good wind proof seal filling all the previous gaps. Most companies will, at the same time, overhaul the windows, replacing sash cords and adjusting weights where necessary, and replacing missing or broken putty. Draughtproofing will pay for itself in one or two years. This compares with a repayment time of 60-100 years for double glazing.

Painting

Where draught-proofing measures have been carried out, special care is needed when painting the windows. Brush-type draught-strips in particular will be ruined once clogged with paint, and although paints will not stick easily to rubber, some solvent paint removers attack plastic.

Mill House Window Workshop also provide draughtseals that do not use brushes but paint resistant polypropylene seals.

If commercially produced sash windows are to be used, whether double glazed or single glazed, they should be ordered primed only and painted on site (again taking particular care over the draught strips). This is because modern factory applied paint coatings can be so perfect that they give the impression that the window is plastic, which has no character, and has no place in historic buildings.

Replacement Windows

Where replacement cannot be avoided, the new design should match the existing windows exactly (see Do's and Don'ts) unless they are clearly modern and out of character with the building. If the existing windows are old, but not as old as the house, the question of whether or not to revert to the original design can pose a dilemma. For example, if all the windows in a Georgian terrace are Victorian, with few glazing bars, the Georgian character of the terrace may be impaired, yet changing those in one house would not only destroy original craftsmanship but would also look odd, damaging the unity of the whole terrace. Similarly, an early box sash window (where the box is on the face of the building) which has had later sashes with fine glazing bars inserted, may appear as an anachronism to the practised eye. Alterations such as these are so common as to be generally regarded as acceptable, forming part of the building's history even though they may 'look wrong'.

A joiner who does not specialise in historic building work may have a very different idea of what constitutes 'new windows to match the existing'. Unless one can have complete confidence that the joiner's claim to specialise in historic building work is genuine, it is safer to draw out the joinery profiles required at full scale, leaving no room for any misunderstanding.

GLOSSARY

ARCH - A support over an opening in a wall, generally curved, but in the context of Georgian buildings often nominally flat (see camber).

ARCHITRAVE - A moulded frame to a door, window, or other opening.

ASTRAGAL - A moulded wooden glazing bar. BAY WINDOW - A projecting window beginning on the ground floor and sometimes embracing several storeys; usually square or canted.

BLIND BOX - A shaped timber pelmet on the outside of a window (generally of the Regency period and later) which concealed a blind when folded away.

BOW WINDOW - A curved bay window.

BOX, BOX FRAME - The outer (hollow) casing of a timber sash box - sash window, which houses the counterbalancing weights, enabling the sashes to move up and down with ease. Early examples were carved out of solid wood, but later made up from separate components.

BOXING - Usually used to describe the space into which internal shutters fold back.

BULL’S·EYE GLASS - The central remnant of a crown glass disc; originally used only in the least important windows.

CAMBER - The very slight arching of the Soffit of a flat arch, typically rising in the middle to a height equal to one hundredth of the width of the arch.

CANTED BAY - a bay window where the sides, instead of being square, are usually at an angle of 45° or 60° to the wall, but which can be as low as 15° (then referred to as a shallow bay).

CASED FRAME, CASING - See box.

CASEMENT WINDOW - A window with the sash, or light hinged at the side so as to open outwards or inwards. A top-hung casement has the hinges at the top and opens outwards.

CILL, SILL - The lowest horizontal member of a timber window; also the projecting stone member on which the window sits.

CONSERVATION - The thoughtful and sensitive treatment of our heritage, in the shape of buildings or groups of buildings, however small or large.

CROWN GLASS - Glass formed by the now obsolete method of spinning molten glass into a disc on the end of a blowpipe; the disc was cooled and then cut into rectangular panes.

CYLINDER GLASS - Sheet formed by blowing an elongated cylinder from molten glass, which is then cut along its length and laid flat, to cool, before being sub-divided into smaller sheets.

DOUBLE GLAZING - Glazing in which two layers of glass are separated by an air space for the purpose of increasing sound-insulation and reducing heat loss. See also sealed unit.

DOUBLE-HUNG - A sash window in which both sashes or sash window - lights are capable of moving up, or down, and are counterbalanced by weights concealed within a sash box.

DRESSINGS - Bricks or stones around openings or at the corners of buildings, of better quality than the material used generally for the walls.

EDGE SEAL - A plastic material used around the outer edges of a sealed unit, usually incorporating a desiccant to absorb moisture.

FENESTRATION - The arrangement of windows in a facade; also refers to the size and proportion of the windows, and sometimes to the subdivision within a window.

FERRAMENTA -Ironwork associated with windows, such as balconies or outside shutter hinges etc.

FITTINGS - Metal parts which enable window sashes, casements, or internal shutters to perform their function.

FLOAT GLASS - Glass sheets made by floating molten glass on a surface of molten metal, thereby producing a smooth relatively flat surface which does not need polishing.

FRAME - See sash.

GAUGED BRICKWORK - Brickwork in which the bricks are measured (‘gauged’), rubbed down accurately to the sizes and shapes required, and laid with very thin joints; often a special bright red brick of fine texture was used for this purpose.

GEORGIAN - A development of the style prevalent in the reign of Queen Anne, and covering the period 1714 (George I) to 1830 (death of George IV), a span of 115 years.

GLAZING BAR - The solid wooden framing piece made to receive panes of glass.

HORNS - A downward extension of the timber side members of the top sash of a 19th century window, initially rounded off, later elaborately shaped.

IRONMONGERY - Internal fittings, not always of iron, such as pulleys, catches, handles and finger pulls.

JAMB - The side of an opening in a wall, for a door or window; or that part of a frame which sits against the side of an opening.

LIGHT - A metal or timber frame with glass panes or quarries which may be fixed or open able.

LINTEL - A beam over an opening in a wall supporting masonry above.

MARGIN LIGHTS - Narrow panes of glass at the edges of a SASH.

MEETING RAILS - The top member of the bottom sash, and the bottom member of the top sash, together

MID FEATHER - A thin piece of wood within the sash box, which keeps the two weights apart as they move up and down; also called a ‘parting slip’.

MULLION - A fixed vertical post or other upright dividing a window into two or more lights.

ORIEL -A projecting window which, unlike a bay, is supported off the face of the building (often by brackets) not off the ground.

PANE - A sheet of glass cut to fit into a light or sash, held in position by astragals or glazing bars.

PARTING BEAD - A narrow vertical strip of wood at the centre of the pulley stile of a sash box, which keeps the top and bottom sashes apart, and allows them to slide past each other; removable for maintenance of the upper sash.

PARTING SLIP - See mid-feather.

PLATE GLASS - Glass of better quality than sheet. POLISHED PLATE - Glass which has been cast flat, then ground and polished and therefore has two smooth faces.

POCKET - A small panel in the box frame, or casing which provides access to the weights. PRESERVATION - The act of defending a cherished building or artefact from destruction. Not always synonymous with the term conservation, which embraces the concept of enhancement by occasionally adding, or even in extremis taking away.

PULLEY - The grooved wheel over which the sash cord passes.

PVCu - Poly vinyl chloride; a type of plastic used extensively for making new and replacement windows.

QUARRY - A small piece of glass, usually rectangular or diamond shaped, leaded into a window.

QUEEN ANNE - Queen Anne's reign (1702-14) saw the development of the earlier forms and styles of building from the times of Charles 11 and William and Mary ('late Stuart'). The term was adopted (not entirely accurately) by the exponents of the 'Queen Anne Revival', to describe a combination of asymmetry, informal planning, and detailing taken from English and Flemish domestic buildings of the 17th and 18th centuries (known at the time as 'Free Classicism') .

REAMY - Used to describe glass with wavy imperfections. See also seed.

REBATE - A rectangular shaped recess cut into the edge of a piece of timber.

REGENCY - Strictly speaking, the period (1811-1820) during which the future George IV took over from his father the 'mad' George III and acted as Regent (i.e. reigning in the place of the King). Generally, in architecture, the term is taken to mean the period from the 1790s to about 1840. It is therefore synonymous with 'late Georgian', and embraces the reign of William IV and the first few years of Queen Victoria's reign.

RENEWAL - The act of restoring to the same condition as when new by repair, with the minimum loss of the original. Not to be confused with replacement.

REPLACEMENT - The act of substituting a new thing for an old thing, frequently without due consideration.

REVEAL - The sides of a door or window opening which are at 90° to the face of the wall in which the opening sits.

SASH - A frame of timber containing glass panes or a single glass pane, originally from the French word chassis (meaning frame). Sometimes confusingly, in older documents, having the same meaning as casement.

SASH BAR - See glazing bar, astragal. SASH BOX - See box.

SASH CORD - A rope, cord, or line fixed to the side of a frame or sash, which passes over a pulley into the box fame and is attached at its other end to a sash weight, made of lead or cast iron.

SASH LINE - See sash cord.

SASH WEIGHT - A piece of lead or iron which counterbalances the sliding sash window, by means of sash cords and pulleys.

SASH WINDOW - A type of timber window in which two frames or sashes slide vertically over each other. Horizontally sliding sash windows also exist, (see Yorkshire lights).

SEALED UNIT - double glazing in which air is withdrawn from the space between two sheets of glass to form a vacuum, and the edges sealed.

SECONDARY GLAZING - A system of sliding or removable inner windows, usually of lightweight construction, intended to increase thermal and acoustic insulation.

SEED - Small air bubbles or other material imperfections found in old glass. See also reamy.

SEGMENTAL HEADED - As opposed to a flat or semi-circular arch or elliptical arch, a curved arch which is formed out of a small segment of a circle. A window in such an arch should normally follow the same curve, but in replacement work the window is often made with a flat head, and the remaining space filled solid.

SHEET GLASS - Ordinary window glass, not of such uniform thickness as float or plate glass.

SINGLE-HUNG - A sash window of which only one sash, usually the bottom one, slides vertically.

SLIDING SASH - A window which slides, usually vertically but sometimes horizontally, within an outer frame.

SOFFIT - The visible underside of a projecting surface, beam or lintel.

SPIRAL BALANCE - A spring-operated substitute for cords, pulleys, and weights in a double-hung sash window, introduced in the 1930's.

STAFF BEAD - A moulded timber member on the inside of a sash box, which keeps the bottom sash from falling out, and is removable for maintenance of the sashes.

STILE - A vertical side piece; that part of a sash box against which the sashes move up or down.

TRANSOM - A fixed horizontal bar of wood or stone across the opening of a window, dividing a window into two or more lights.

VOUSSOIR - A shaped brick or piece of stone forming part of an arch.

WEIGHT - See sash weight.

YORKSHIRE LIGHTS - Horizontally sliding window frames, sashes, or lights; usually in a pair, one fixed and one moving, but sometimes in threes (the central panel normally being fixed).

Recommended Reading

Counsel, S: The Good Wood Guide. Friends of the Earth, London.

The Care and Conservation of Georgian Houses. Edinburgh New Town Conservation Committee.

Louw, Hentie: Colour Combinations. Architects Journal, 4th July 1990.

Louw, Hentie: The Origin of the Sash Window. Architectural History, Volume 26, 1983.

Louw, Hentie: Window-Glass Making in Britain c. 1660 - c. 1860 and its Architectural Impact. Construction History, Volume 7, 1991.

Small, Tunstall and Woodbridge, Christopher: Mouldings and Turned Woodwork of the 16th, 17th and 18th Centuries.

Technical Pamphlet 13; The Repair of Wood Windows. Society for the Protection of Ancient Buildings.

Suddards, Roger and Hargreaves, June M; Listed Buildings, 3rd edition.

Taylor, Jonathan: The Conservation and Thermal Improvement of Timber Windows. The Building Conservation Directory 1996.

Wrightson, David: Mandatory Double Glazing (?) Heat Loss versus Conservation. Context (The Journal of the Association of Conservation Officers) No.s 45 and 46.

Building Research Establishment publications:

Information Paper: In situ Treatment for Existing Window Joinery

Digest 304: Preventing Decay in External Joinery

Digest 201: Wood Preservation Application Methods

Information Paper 1 P 16/87; Maintaining Paintwork on External Timber.

English Heritage publications:

Listed Building Guidance: Dormer Windows Framing Opinions; A National Campaign to Protect our Legacy of Windows and Doors

Principles of Repair.

The Author

David Wrightson MCD BArch RIBA Dip Conservation (loMS) is a partner in Lawrence & Wrightson, Architects and Landscape Architects, Chiswick, London.